Photovoltaic modules

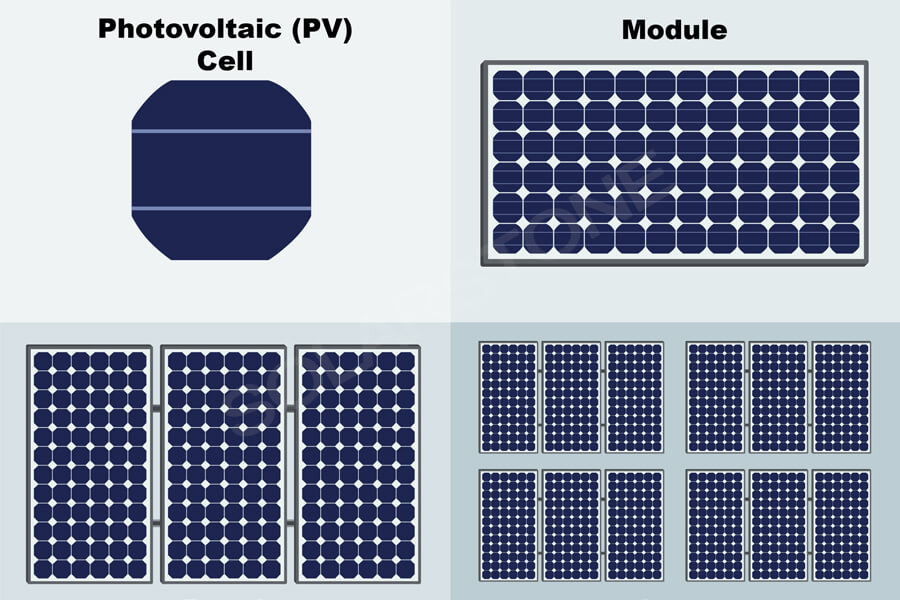

Photovoltaic modules are the core of photovoltaic power generation systems. Photovoltaic modules are a combination device of photovoltaic cells that can provide direct current output separately and are minimally indivisible, with packaging and internal connections. They are also a direct carrier for downstream terminals.

From the necessity of photovoltaic modules:

(1) Due to the low output voltage of individual solar cells, they cannot meet the voltage requirements of general electrical equipment. Therefore, a certain number of individual solar cells need to be sealed in series or parallel to form photovoltaic cell modules before they can be used as power sources;

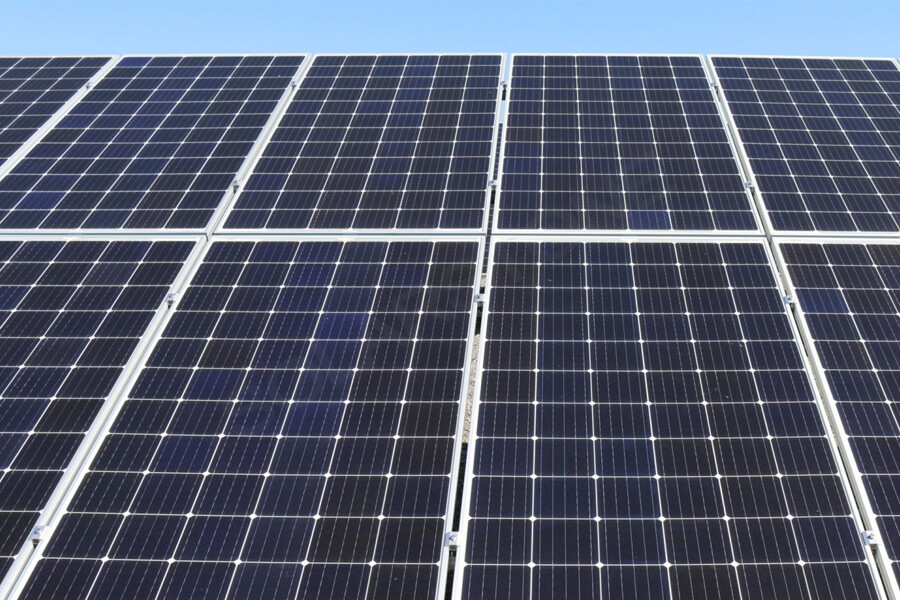

(2) Unpacked solar cells are affected by the environment, and the electrodes are prone to corrosion and detachment in the air. They have poor weather resistance and decay quickly. Encapsulating solar cells as photovoltaic modules can effectively prevent corrosion of the solar cell electrodes and interconnections.

From the perspective of the importance of photovoltaic modules, under the trend of silicon wafer thinning, solar cells have become more fragile. Module packaging can effectively avoid solar cell fragmentation and is more convenient for handling and outdoor installation. Therefore, the quality of solar module packaging will directly determine the service life and reliability of photovoltaic cells.

Photovoltaic module technology

The processing of photovoltaic modules consists of welding, stacking, laminating, framing, testing and other processes, and the level of technology directly affects the quality and grade of solar modules.

From the perspective of processing technology, the current mainstream photovoltaic module processing technology includes multiple processes such as solar cell sorting, machine welding, stacking, lamination, EL testing, framing, junction box installation, cleaning, IV testing, and finished product inspection.

The various processes in the processing of photovoltaic modules are interrelated. Improper processing may lead to a series of problems such as solar cell cracking, insoluble EVA, bubbles, black/dark films, foreign objects, poor spacing, cracks, chipping/chipping, offset of solder strips, virtual soldering/over soldering, grid breakage, adhesive bubbles, etc.

In order to operate reliably for a long time under harsh outdoor conditions, the processing of photovoltaic modules requires high technological requirements, and the level of each process directly affects the quality and grade of the product.

From the perspective of processing equipment, solar module equipment corresponds to the various process flows of solar module preparation, mainly including laser slicing machines, string welding machines, automatic stacking equipment, layer presses, and automatic assembly lines.

Photovoltaic module industry

Photovoltaic modules have both ToB and ToC properties, with downstream being photovoltaic power station systems. Photovoltaic modules are located at the end of the manufacturing process in the photovoltaic industry chain, directly facing the end application market, and downstream is the photovoltaic power station system.

According to different installed capacity and grid voltage, photovoltaic power stations can be divided into centralized (large ground power stations, etc.) and distributed (industrial, commercial, household, etc.).

The business model of photovoltaic modules has both the product and cost attributes of ordinary ToB manufacturing industry, as well as the brand and channel attributes of ToC industry. Customers mainly include end owners, EPC, distributors, and installers.

The solar modules purchased by owners and EPC are mainly used in ground power plants, and downstream are large enterprises; The solar modules purchased by distributors and installers are mainly used in distributed power plants, downstream including ordinary households and small and medium-sized enterprises.

In recent years, with the increase in the proportion of household distributed installed capacity and the continuous decrease in the cost of solar modules, the types of end customers of solar module enterprises are diversifying and the scale is gradually expanding, and the ToC attribute of the component industry is also gradually strengthening.